Ƙofofin tsarin allo na aluminum da tagogi sune bayanan martaba waɗanda za a yi musu magani. Abubuwan firam ɗin ƙofa da taga waɗanda aka yi ta hanyar ɓarna, hakowa, niƙa, tapping, yin taga da sauran fasahohin sarrafawa, sannan a haɗa su tare da sassan haɗawa, sassan rufewa, da kayan buɗewa da rufewa.

Aluminum alloy tsarin kofofi da tagogi za a iya raba zuwa zamiya kofofi da tagogi, cakument kofofi da tagogi, allon kofofi da tagogi, ciki budewa da jujjuya windows, rufofi, kafaffen tagogi, rataye tagogi, da dai sauransu bisa ga tsarin da budewa da kuma hanyoyin rufewa. Dangane da bayyanar daban-daban da kyalkyali, kofofin tsarin gami na aluminum da tagogi za a iya raba su zuwa launuka da yawa kamar fari, launin toka, launin ruwan kasa, hatsin itace, da sauran launuka na musamman. Bisa ga daban-daban samar jerin (bisa ga nisa na sashe na kofa da taga profile), aluminum gami kofofin da windows za a iya raba zuwa 38 jerin, 42 jerin, 52 jerin, 54 jerin, 60 jerin, 65 jerin, 70 jerin, 120 jerin, da dai sauransu

1. Qarfi

Ƙarfin ƙofofi da windows na tsarin haɗin gwiwar aluminum yana nunawa ta hanyar matakan iska da aka yi amfani da su a lokacin gwajin matsa lamba na iska a cikin akwatin matsa lamba, kuma naúrar ita ce N / m2. Ƙarfin aluminum gami kofofin da windows tare da talakawa yi iya isa 196l-2353 N / m2, da kuma ƙarfin high-yi aluminum gami windows iya isa 2353-2764 N / m2. Matsakaicin matsawa da aka auna a tsakiyar akwati a ƙarƙashin matsin da ke sama yakamata ya zama ƙasa da 1/70 na tsayin gefen ciki na firam ɗin taga.

2. Tsantsar iska

Tagar alloy na aluminum yana cikin ɗakin gwajin matsa lamba, ta yadda gaba da bayan taga suna samar da bambancin matsa lamba na 4.9 zuwa 9.4 N/m2, kuma ƙarar samun iska ta kowane yanki m2 a kowace h (m3) yana nuna rashin iska na taga, kuma sashin shine m³/m²·h. Lokacin da bambancin matsa lamba tsakanin gaba da baya na aluminum gami taga tare da talakawa yi ne 9.4N/m2, da airtightness iya isa kasa 8m³/m²·h, da aluminum gami taga tare da high airtightness iya isa kasa 2 m³/m²·h. da

3. Tsantsar ruwa

Ƙofofin da tagogin tsarin suna cikin ɗakin gwajin matsa lamba, kuma a waje na taga yana fuskantar matsin lamba na sine tare da tsawon lokaci na 2s. A lokaci guda, 4L na ruwan sama na wucin gadi yana haskakawa zuwa taga a cikin adadin 4L a kowace m2 a cikin minti daya, kuma ana yin gwajin "iska da ruwan sama" na minti 10 a ci gaba. Kada a sami fitowar ruwa a bayyane a gefen gida. Rashin ruwa yana wakilta ta daidaitaccen matsa lamba na iska mai bugun da aka yi amfani da shi yayin gwajin. Tagar alloy na al'ada na yau da kullun shine 343N/m2, kuma taga mai jurewa mai ƙarfi mai ƙarfi zai iya kaiwa 490N/m2.

4. Rufin sauti

Ana gwada asarar watsa sauti ta tagogin allo na aluminum a cikin dakin gwaje-gwaje na sauti. Ana iya gano cewa lokacin da mitar sauti ta kai wani ƙima, asarar watsa sautin tagar alloy na aluminium yakan yi tsayin daka. Yin amfani da wannan hanya don ƙayyade matakin matakin aikin haɓakar sauti, asarar watsa sauti na tagogin alloy na aluminum tare da buƙatun sauti na sauti zai iya kaiwa 25dB, wato, za a iya rage matakin sauti ta 25dB bayan sautin ya wuce ta taga alloy na aluminum. Aluminum gami windows tare da high sauti rufi yi, da sauti watsa asarar matakin kwana ne 30 ~ 45dB.

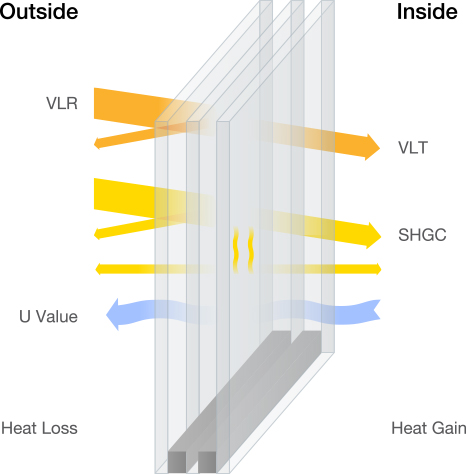

5. Thermal rufi

Ana nuna aikin haɓakar zafi ta hanyar ƙimar juriya mai zafi na taga, kuma naúrar shine m2 • h • C / KJ. Akwai matakai uku na rabon kuɗi na yau da kullun: R1=0.05, R2=0.06, R3=0.07. Yin amfani da 6mm glazed biyu-glazed high-performance thermal rufi windows, thermal convection juriya darajar iya isa 0.05m2• h • C / KJ.

6. Dorewa na Nailan Guide Wheels

Ana amfani da tagogi masu zamewa da injina masu motsi don ci gaba da maimaita gwaje-gwajen tafiya ta hanyoyin haɗin kai. Diamita dabaran nailan shine 12-16mm, gwajin shine sau 10,000; diamita dabaran nailan shine 20-24mm, gwajin shine sau 50,000; Nailan dabaran diamita ne 30-60mm.

7. Ƙarfin buɗewa da rufewa

Lokacin da aka shigar da gilashin, ƙarfin waje da ake buƙata don buɗewa ko rufe akwati ya kamata ya kasance ƙasa da 49N.

8. Buɗewa da rufewa

Makullin buɗewa da rufewa yana motsa motar akan benci na gwaji, kuma ana ci gaba da gwajin buɗewa da rufewa a cikin saurin sau 10 zuwa 30 a cikin min. Lokacin da ya kai sau 30,000, kada a sami lalacewa mara kyau.

Lokacin aikawa: Yuli-24-2023